Shaft Alignment Hunter Valley

Rotating machines are prone to misalignment. Correctly aligned and regularly controlled machines significantly reduce operating and maintenance costs. Conventional methods for shaft alignment, such as straightedge, thickness gage or dial gage, are very time consuming. The quality of the results also highly depends on the experience of the operator.

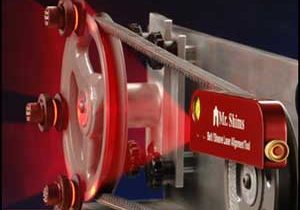

Lasaligns PRUFTECHNIK laser measuring devices use unique state-of-the-art technology to ensure maximum precision alignment of shafts.

Precise alignment pays off in many ways:

- Reduce power consumption

- Decrease wear on bearings, seals, shafts and couplings

- Avoid overheating of bearings and couplings

- Reduce vibrations in shafts and foundation bolts

- Significantly reduce damage to shafts and foundation bolts.

Also check out the Pruftechnik site.

We understand conditions such as soft foot and thermal growth.